The Safety Overhead Suspension Crane is a reliable and efficient solution for lifting heavy loads in industrial settings. With a maximum weight capacity of [insert weight capacity], this crane is designed to handle even the toughest tasks. Its overhead suspension system ensures stability and safety during operation, minimizing the risk of accidents or injuries. The crane is equipped with advanced safety features such as overload protection and emergency stop buttons, providing peace of mind to users. Its durable construction and high-quality materials guarantee long-lasting performance. The Safety Overhead Suspension Crane is the perfect choice for any industry looking to enhance productivity while prioritizing safety.

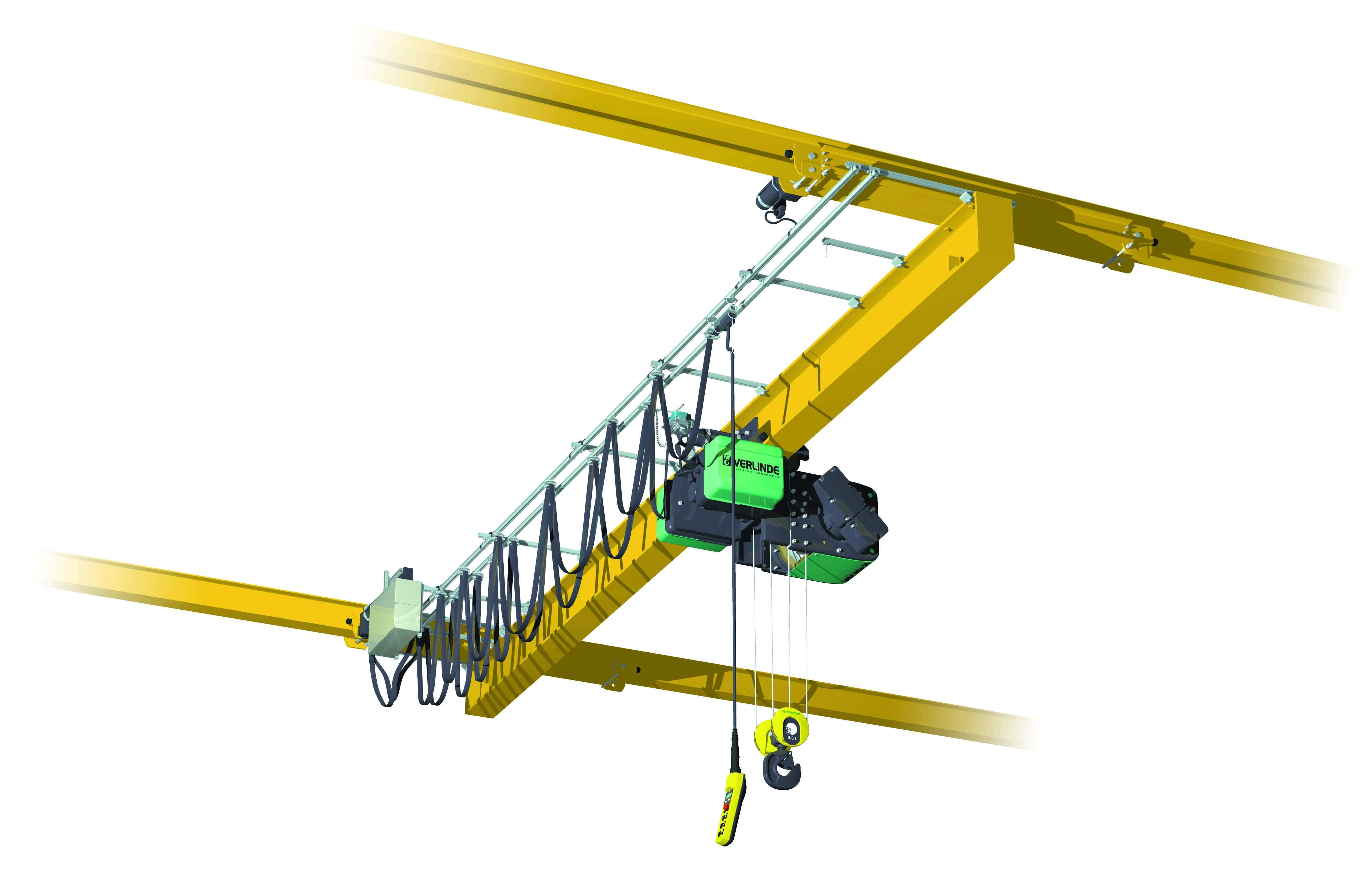

Safety Overhead Suspension Crane

Description

The suspension crane can be directly installed on the roof of existing plants without brackets to save space and cost for customers. In addition the entire plant space will be used for production. The running limit dimension for trolley of the electric suspension crane is small.The heavy object can be lifted to the position very close to the ground of plant.The running range of trolley will exceed the span of crane through the side jib.

Fatures and advantages

1、Hoisting motor unit

a) 3-in-1 driving module consist of motor, gearbox and brake which is easy for maintenance and replacement.

b) Compact structure specially designed for hoisting mechanism.

c) High efficiency to ensure low energy consumption low noise and eco-friendly design.

d) Asbestos-free brake sustain the work life of one million times.

e) Maintenance-free.

f) Two step upper and two step lower Limit Switch.

2、Cross Travel

a) 3-in-1 driving module consist of motor, gearbox and brake which is easy for maintenance and replacement.

b) Inverter control supports a smooth and reliable cross travelling movement.

c) Low energy consumption low noise and eco-friendly design.

d) Asbestos-free brake disc and its normal services life can be up to one million times.

e) Maintenance-free.

f) Two step limit switch.

3、Long Travel

a) 3-in-1 driving module consist of motor, gearbox and brake which is easy for maintenance and replacement.

b) Inverter control supports a smooth and reliable long travelling movement.

c) Low energy consumption low noise and eco-friendly design.

d) Asbestos-free brake disc and its normal services life can be up to one million times.

e) Maintenance-free.

f) Two step limit switch.

g)With special technology to avoid crane skewing.

4、Electric Hoist

a) Fully developed by Eurocrane which is strictly following FEM standard for lifting equipment.

b) Safety monitor to collect the operating data for easy maintenance and record.

c) Light weight and wear resisted rope guide to protect the Wire Rope in drum groove.

d) British and Korea imported wire rope with 2160Mpa high tensile strength and galvanized process to ensure the long service life of the hoist.

e) Drum is fabricated from Q345 seamless pipe which is specially made for drum fabrication. 100% radio grafic tested for defects to ensure high performance.

f) Hook dimension is following DIN standard. Forged by high strength material of grad T. Hooks are 100% redio grafic tested before assembly.

g) IP55 protection grade for electrical cabinet.

5、Electrical control system

a) The electrical system is closed in robust steel plate cabinet, on the crane girder. Class of insulation is IP 55.

b) All movements can be switched off by actuating the emergency-off switch at the control station via a main contactor.

c) Electrical system are fully coded by internal system to ensure quick installation and commissioing.

d) The power supply from the crane to the hoist unit is by means of a highly flexible flat cable.

e) Long and cross travel limited by means of two step switches

f) Overload protection: In the event of overload, the hoist unit switches off and only the lowering motion is possible

g) HBC high class remote control.

Product Display