Introducing our top-of-the-line Wire Rope, an essential component for any crane! Designed with utmost precision and durability, this high-quality rope ensures optimal performance and safety during heavy lifting operations. Crafted from premium-grade steel, it boasts exceptional strength and resistance to wear, guaranteeing a long lifespan and minimal maintenance. With its impressive load-bearing capacity, our Wire Rope effortlessly tackles even the most demanding tasks, making it a must-have for construction sites, warehouses, and industrial settings. Trust in our Wire Rope to provide unparalleled reliability and efficiency, enabling seamless crane operations and ensuring the utmost safety for your workforce.

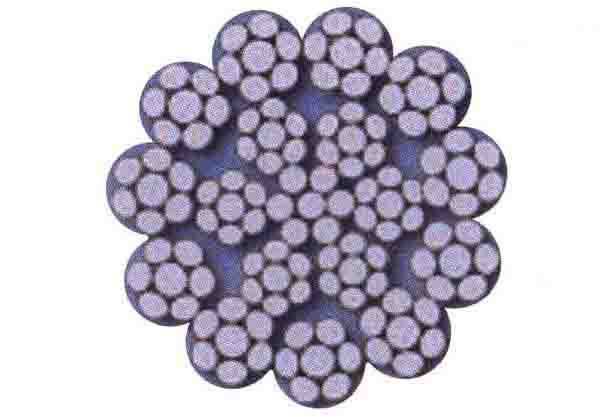

Made of multiple strands wound together, the Steel Wire Rope is one of the most crucial components in a crane. Each strand has a tensile strength ranging between 1470 N/mm2 and 2160N/mm2.As the load carrying rope used in the hoisting mechanism, it can be sent through different surface treatment to suit specific environmental condition.

Technical Features

Wire Rope-Important part of Crane

Product Introduction of Crane Parts

Electric Wire Rope Hoist part of Crane is one of the most crucial components in a crane. Each strand has a tensile strength ranging between 1470 N/mm2 and 2160N/mm2. As the load carrying rope used in the hoisting mechanism, it can be sent through different surface treatment to suit specific environmental condition. It is made of multiple strands wound together.

Product Features:

Designed for higher breaking strength and better strength to weight ratio, our Crane Wire Rope is made of high-toughness steel wires that have been stretched to their tolerance limit prior to being stranded together to form a rope with optimum spacing between each strand.

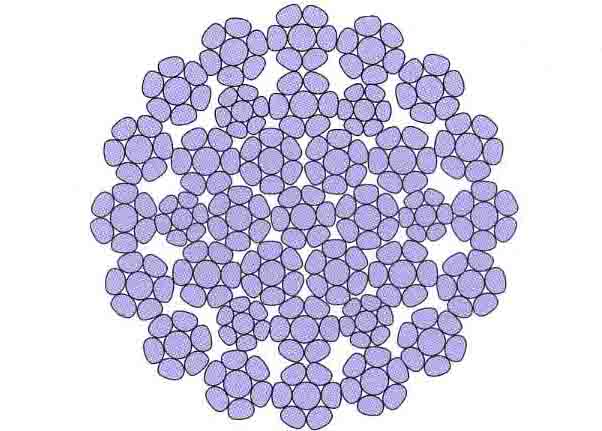

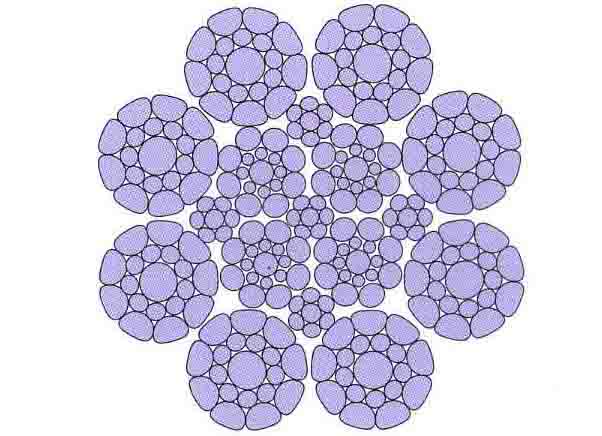

Even if wire strands are tightly twisted, there still be spaces in places where the strand touches with each other. To improve the fill factor of the wire rope, we have added irregularly-shaped wire strand to the rope and sent it through rotary swaging process. Steel wires that are laid in a parallel pattern increase the cross section of the rope.

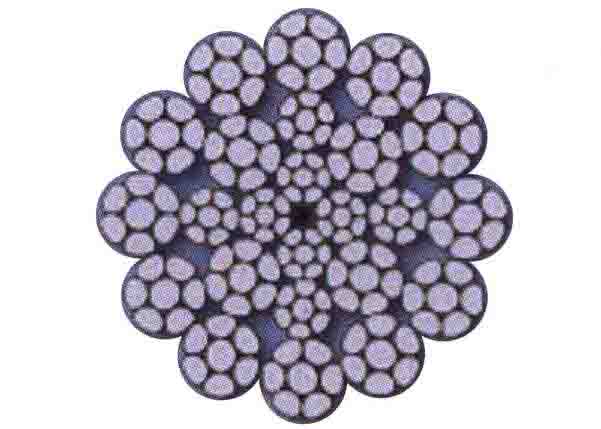

Special-purpose steel rope is commonly seen in various engineering projects. Via precision design and rigorous test, the rope usually can meet very high safety standards. A large number of wires are arranged in a parallel pattern to form a strand. Various strands then are twisted to produce the steel rope. Such a rope-making method ensures an improved safety performance of the rope

Our rotation-resistant wire rope contains several strands laid helically around an independent rope core. The lay direction of outer strands is opposite to that of the independent core so that the overall rope can be non-rotating. This series of rope mainly functions as a lifting tool in the crane. It also can be used in a rope take-up system that requires many times of rope winding.

Increasing the number of strands within a rope and wires in a strand can lead to an extended contact between the rope and the sheave groove or grooved cable drum, thereby reducing the stress acted on average rope. Through adding irregularly-shaped strand to the wire as well as rotary

Swaging process, this contact area will increase to greater extent, as with the decrease of rope stress. Greater flexibility of our steel wire rope means that it can be wound in smaller, tighter circular patterns. When installing the rope onto the drum assembly, its steel and plastic combination design will increase the stability of the whole structure, avoiding internal wire breaking which in turn extends its use life.

Parameters or Specifications:

D: 6, 8, 11, 15……

L: 35, 55, 85, 100......

Product Display: